Robotic Automation

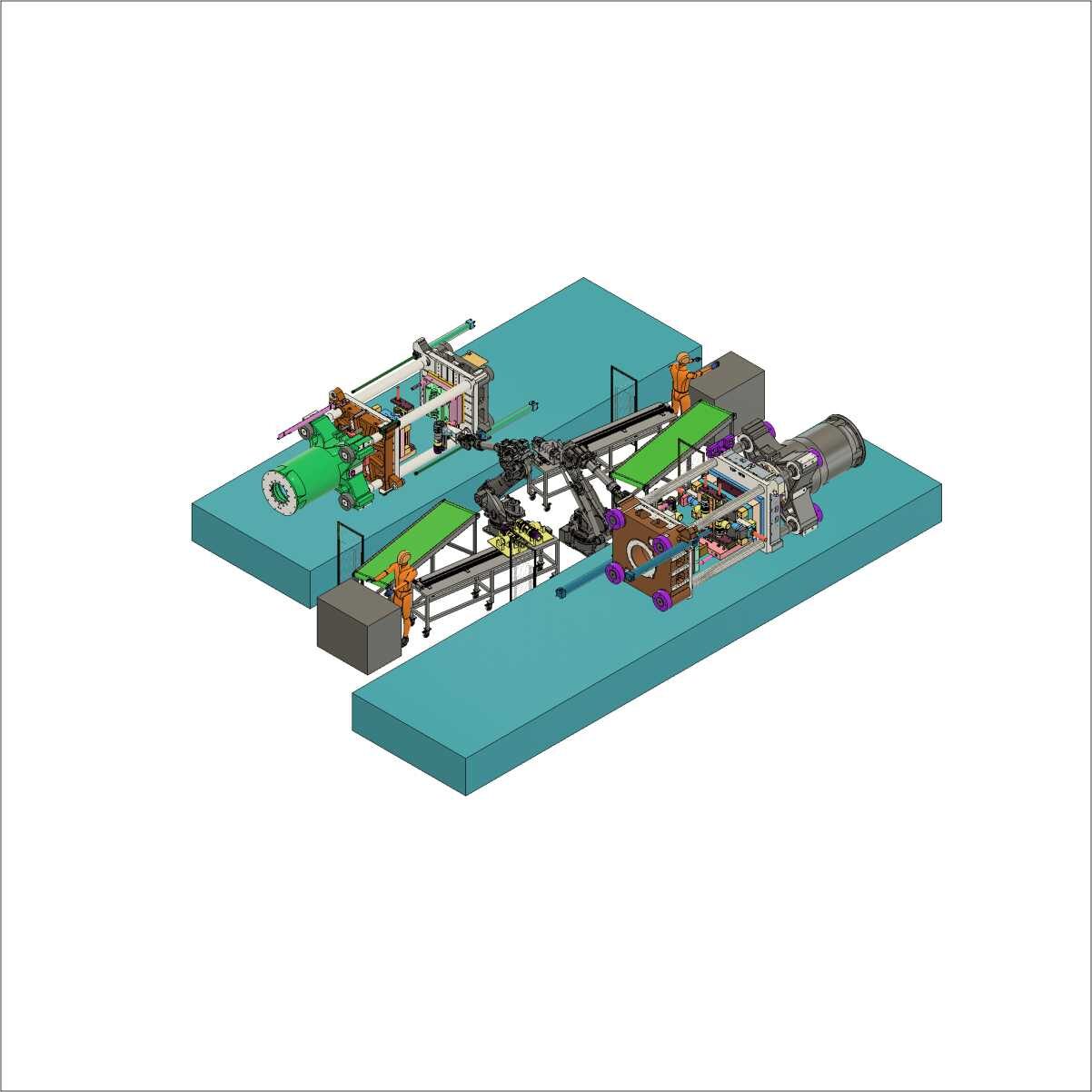

Suprak offers turnkey robot-based automation systems for a whole range of industries and applications including

Suprak has also developed its own 4 axis robots for all-purpose application in presses for Consumer Goods Industries.

We have Unique Capability to Integrate a full range of robots in Industry into customer machine and applications like Mitsubishi, Kawasaki, Motoman, ABB, Fanuc, Borunte.

Suprak is authorized dealer for A&P Industry Co. Ltd in INDIA.

Some Application Developed by SUPRAK

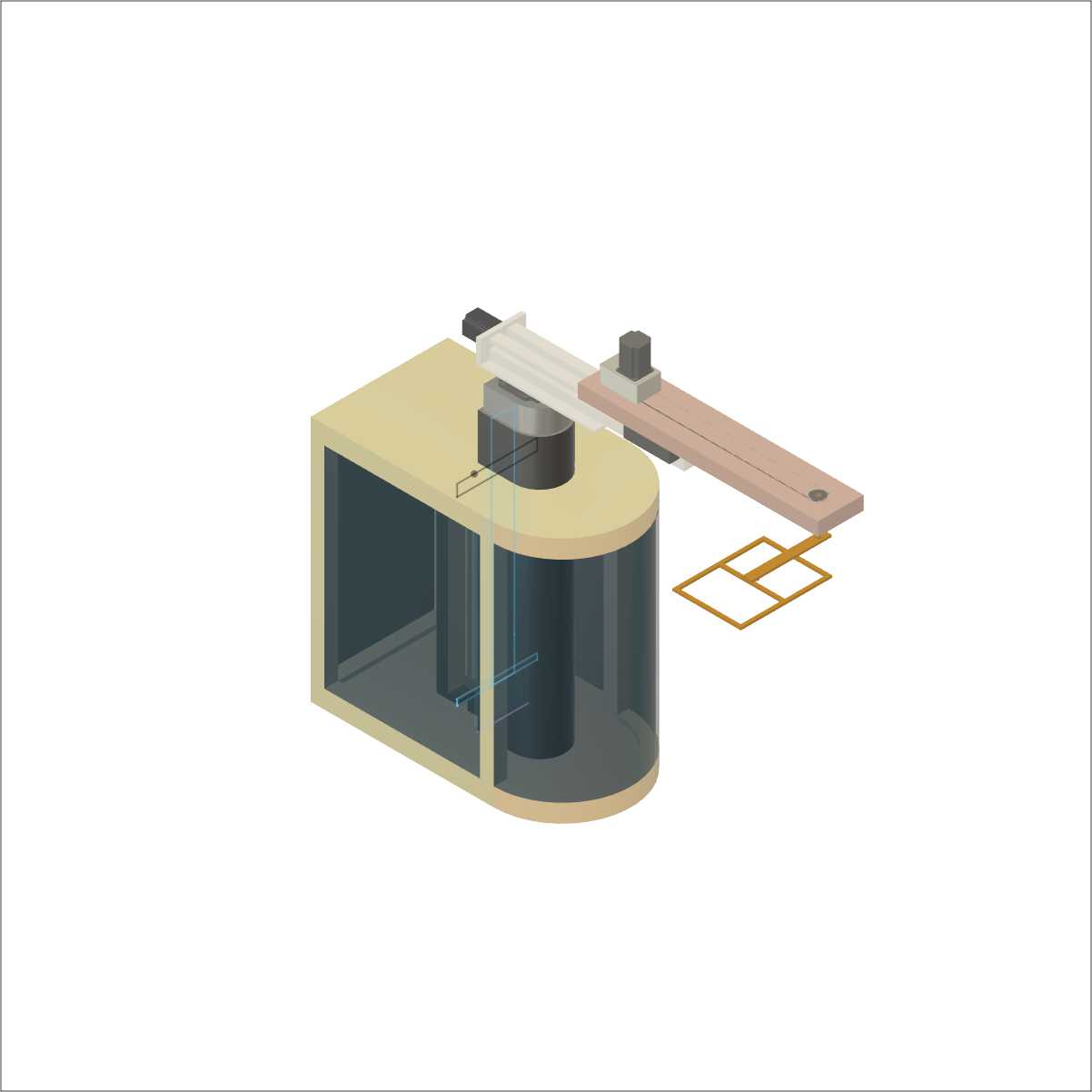

4 Axis Subot for All Purpose Application in Presses for Consumer Goods Industries

Swing-arm Robot

The swing – arm robot is applicable to all types of horizontal injection machine of 30T-150T for takeout products and sprue. Vertical arm is single type. The single function is to clamp products, and the full function is to take out products and sprue. After installing this robot, the productivity will be increased 10-30%, reduce defective rate, ensure safety of operators, reduce manpower and accurately control the output to reduce waste.

Three-axis Servo Manipulator

Series is applicable to all types of horizontal injection machine ranges of 160T-500T for takeout products. Vertical arm is a telescopic type with product arm. Three axis AC servo drive, save time than similar models, accurate positioning and short forming cycle. After installing this robot, the productivity will be increased 10-30%, reduce defective rate, ensure safety of operators, reduce manpower and accurately control the output to reduce waste.

Three-axis driver and controller integrated system: Less connecting line, long distance communication, good expansion performance strong anti interference ability, high repeat precision, can simultaneously control multiple axis, simple equipment maintenance, low failure rate.

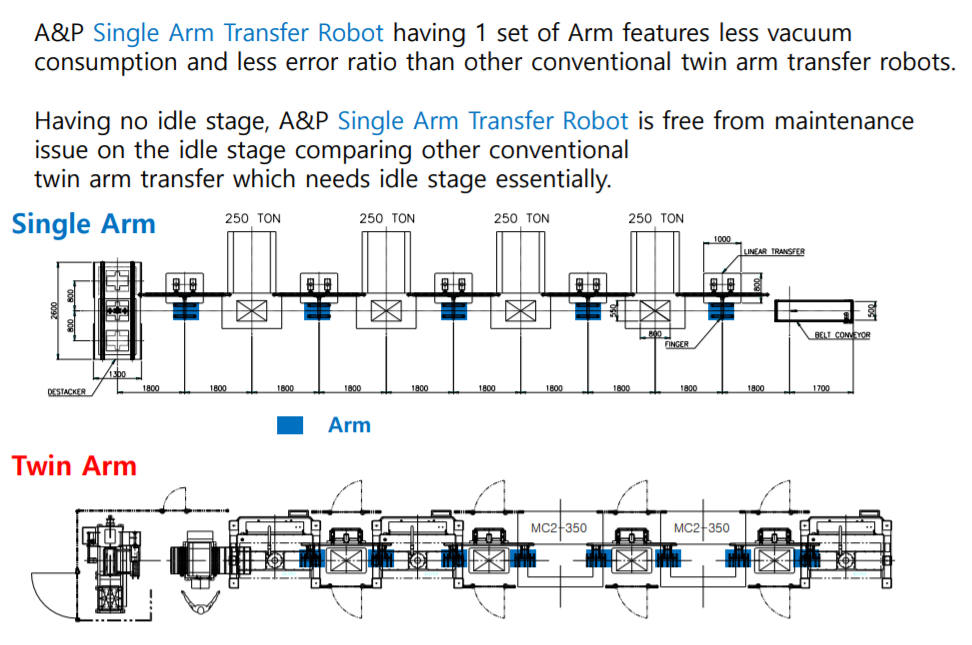

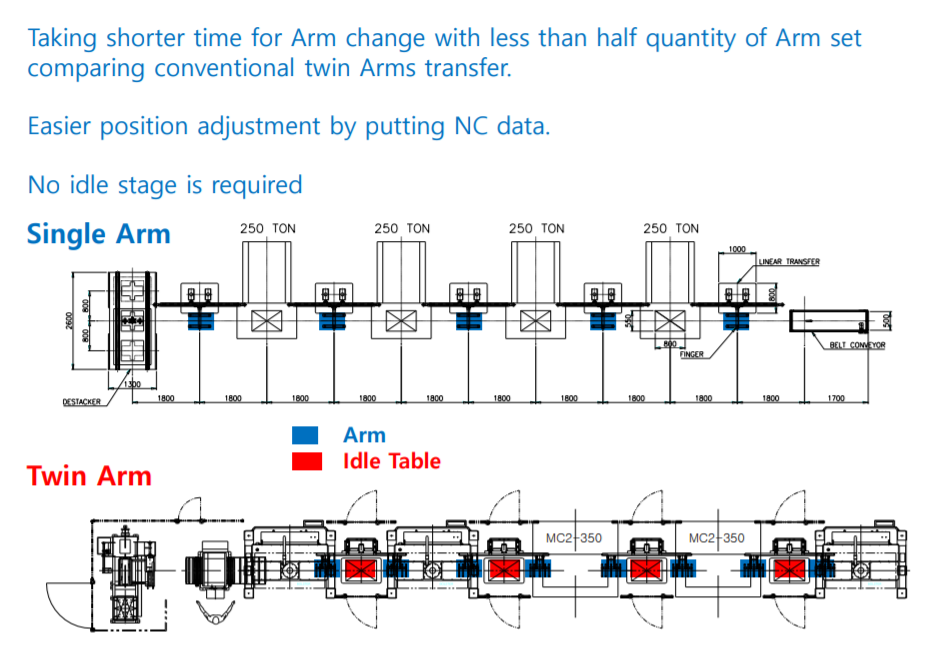

Single-arm Transfer Robot

■ Flexible Robot’s location minimize floor occupying space.

■ No need to make each pass-line height same.

■ Taking less cycle time by letting Press work without stopping at top position – Continuous press work

■ Easier position adjustment by putting NC data.

■ No idle stage is required