Ultrasonic Equipment

Suprak develops Ultrasonic Equipments which reduces the efforts of the customers and helps in smooth productions.

Digital Ultrasonic Welding Machine

Features:-

1. Automatic tuning system, with last cycle memory closed loop feedback of frequency allows faster, more efficient ultrasonic stack start-up

2. Automatic detect faults and display

3. The accuracy of time control up to 0.001 seconds

4. Multi welds modes optional:

– Time mode

– Energy mode (optional)

– Distance mode (optional)

– Continuous mode (optional)

– Auto. Mode (optional)

5. Through internal signal output can be directly connected with the automatic mechanical system

6. The original imported Germany (PINOT) amplitude automatic constant circuit board, vibration board

7. Full Imported Configuration of the machine :original Germany (PINOT) transducer, solenoid valve (Germany FESTO), Pressure gauge (FESTO), Process Control (OMRON), Filter (Japan SMC), PLC(Japan PANASONIC), Human-machine interface (Taiwan We in view)

8. Password Protection. Limits parameter access to qualified personnel only.

9. Touch screen, more convenience

10. CE Approved

1. Automatic tuning system, with last cycle memory closed loop feedback of frequency allows faster, more efficient ultrasonic stack start-up

2. Automatic detect faults and display

3. The accuracy of time control up to 0.001 seconds

4. Multi welds modes optional:

– Time mode

– Energy mode (optional)

– Distance mode (optional)

– Continuous mode (optional)

– Auto. Mode (optional)

5. Through internal signal output can be directly connected with the automatic mechanical system

6. The original imported Germany (PINOT) amplitude automatic constant circuit board, vibration board

7. Full Imported Configuration of the machine :original Germany (PINOT) transducer, solenoid valve (Germany FESTO), Pressure gauge (FESTO), Process Control (OMRON), Filter (Japan SMC), PLC(Japan PANASONIC), Human-machine interface (Taiwan We in view)

8. Password Protection. Limits parameter access to qualified personnel only.

9. Touch screen, more convenience

10. CE Approved

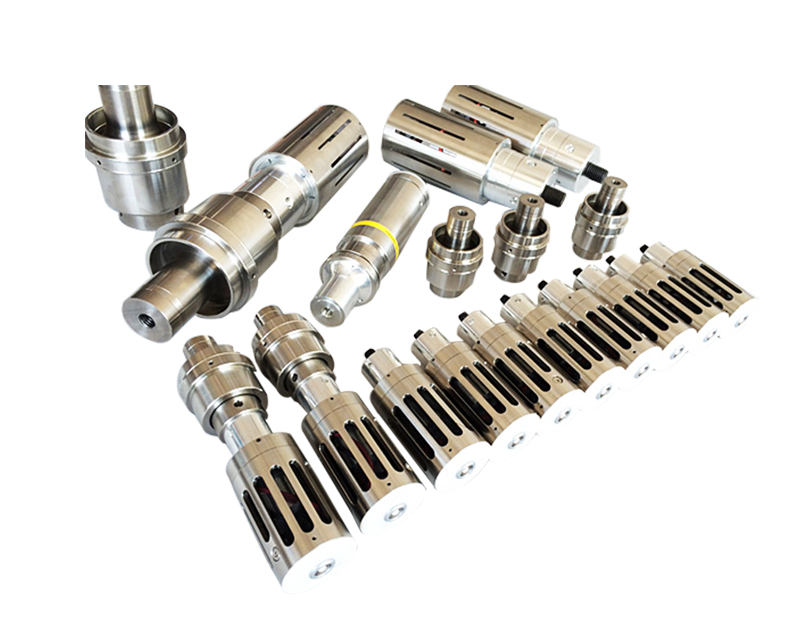

Ultrasonic Converter & Booster

Suprak provides a wide range of high quality ultrasonic transducer, No matter what kind of transducer you are looking for, We can make sure that you can find one at here. It is by utilizing piezoelectric effect to convert electrical energy into mechanical energy. The bolt-on type can make sure that the transducer can produce stable ultrasonic when the load changes.

Also we can offer the ultrasonic converter and booster for a different brand ultrasonic machine like BRANSON, RINCO, Telsonic etc.

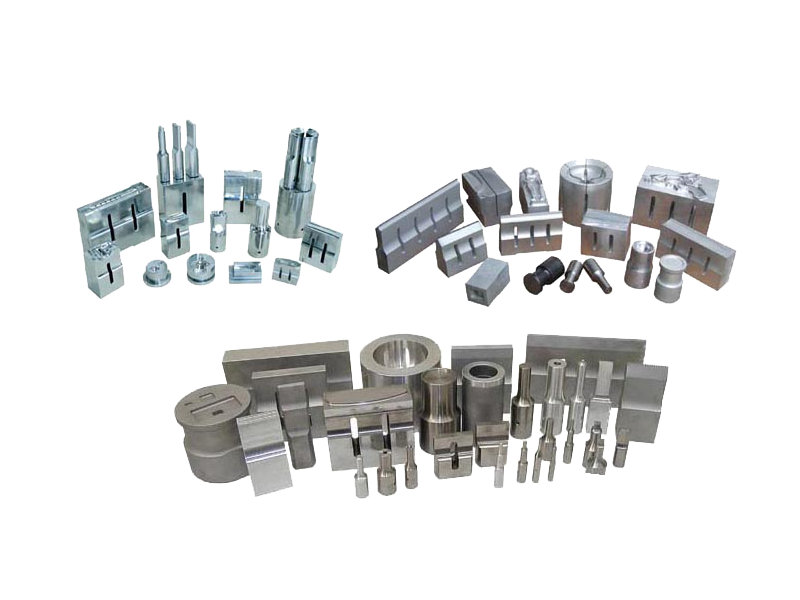

Ultrasonic Horn/Sonotrode

How to Choose The Ultrasonic Welding Machine Horn?

1. What’s the application?

Welding , staking/ferming, Insertion , spot welding , degating, or film sealing etc.

2. What’s the material of horn you can use?

We need according to your application to introduce the horn material to you. Usually it has Titanium, Steel, Aluminium material this three kind material. If you make the horn used for welding the plastic toys. Usually we will suggest using the Aluminium material, it’s cheaper. If your budget is enough, you can use the Titanium material also.

It’s not so easy wear .but the price is much expensive .

3. What’s the size (welding area ) of horn?

It’s also an factor to choose which material of horn and frequency of horn to you .

4. What’s your budget?

Different material ultrasonic horn the price is different .

1. What’s the application?

Welding , staking/ferming, Insertion , spot welding , degating, or film sealing etc.

2. What’s the material of horn you can use?

We need according to your application to introduce the horn material to you. Usually it has Titanium, Steel, Aluminium material this three kind material. If you make the horn used for welding the plastic toys. Usually we will suggest using the Aluminium material, it’s cheaper. If your budget is enough, you can use the Titanium material also.

It’s not so easy wear .but the price is much expensive .

3. What’s the size (welding area ) of horn?

It’s also an factor to choose which material of horn and frequency of horn to you .

4. What’s your budget?

Different material ultrasonic horn the price is different .