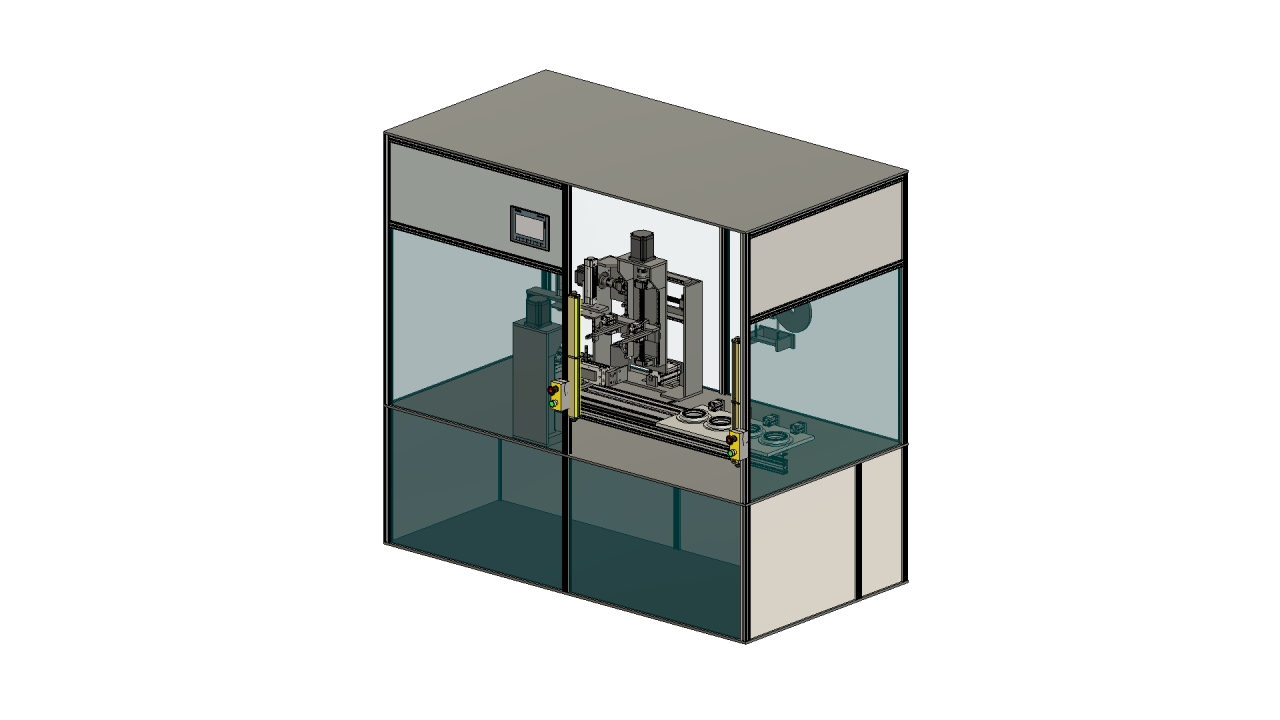

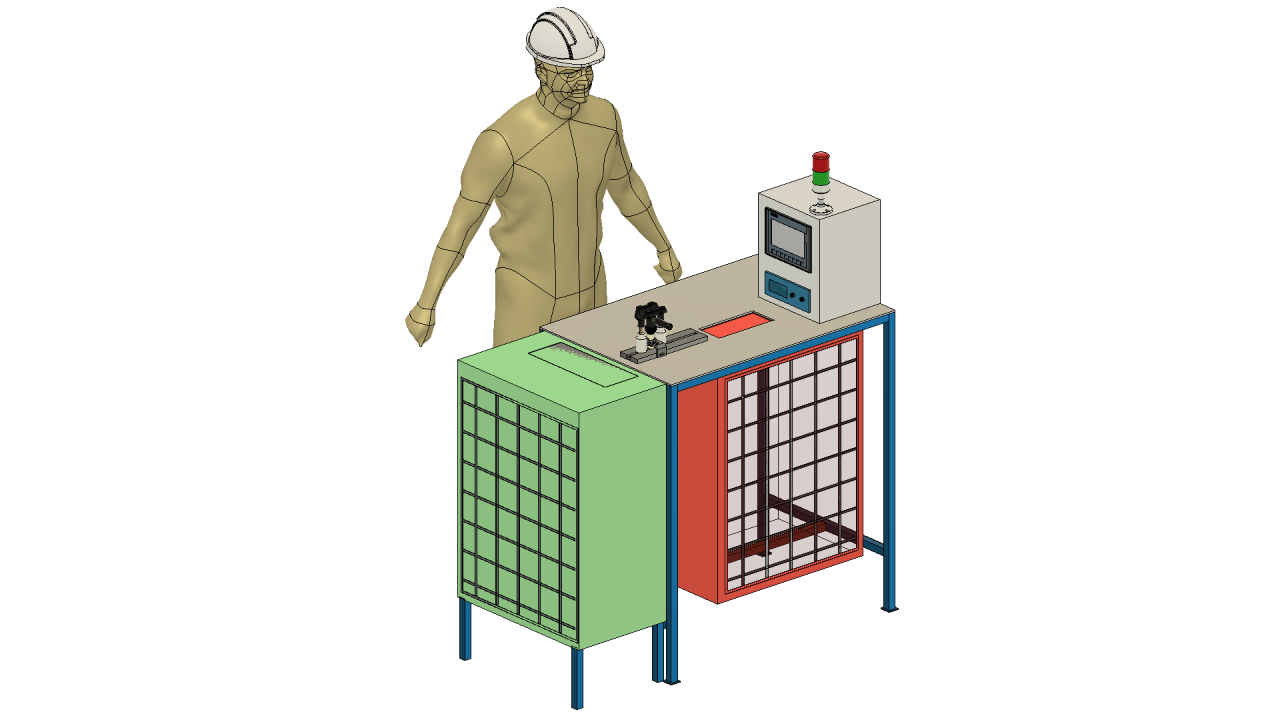

Special Purpose Machine

Suprak develops SPM, which reduces the efforts of the customers and helps in smooth productions.

We Deal with

Belt Conveyors, Pallet Conveyors, Vibratory Bowl Feeder, Fixtures, Mounting Assembly.

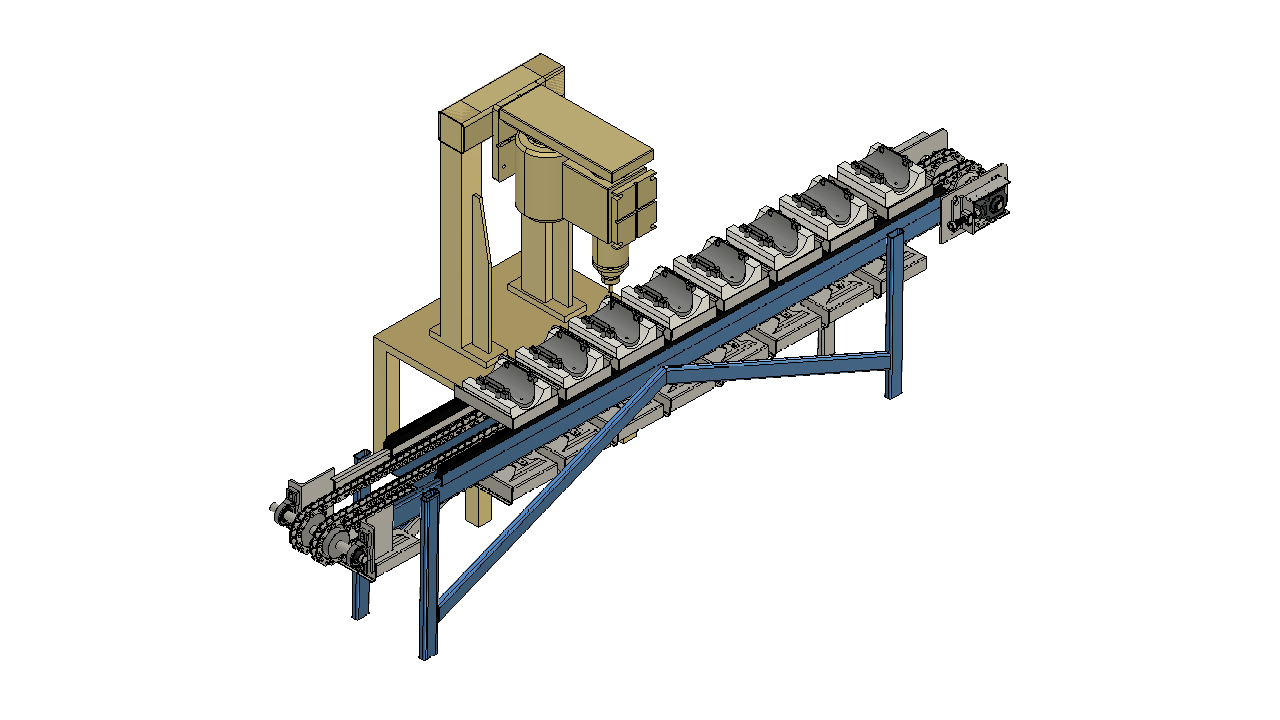

Belt Conveyors

A belt conveyor system can be implemented with a very economical cost per foot of the conveyor for many warehouse and industrial applications. Because it includes just one motor and a simple belt system, they are quite simple. Hence, they’re often one of the first productivity improvement purchases that a growing company will make. Although there are many belt conveyor types, the simplest style is known as a slider bed style. When linked together with sensors and other automation equipment, a conveyor belt system can greatly enhance productivity.

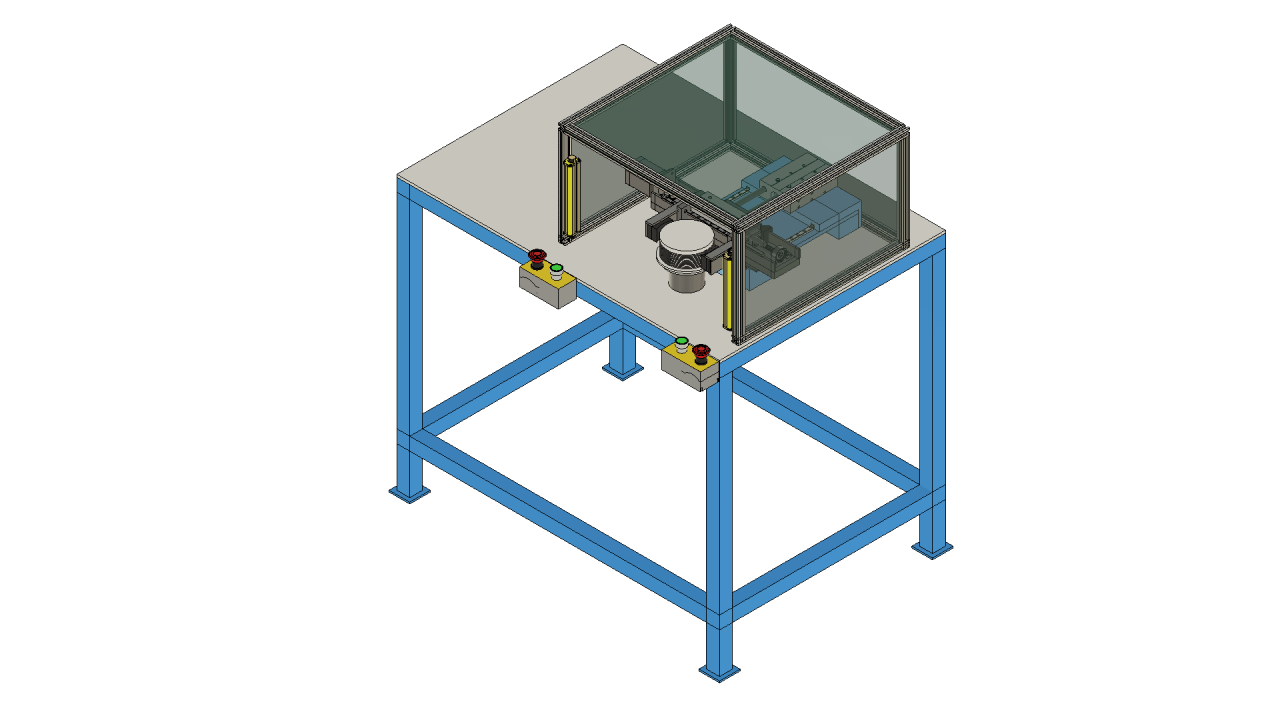

Pallet Conveyors

Pallet handling conveyors are not a one-size-fits-all solution for manufacturing facilities, warehouses and distribution centers. Our Solutions integrate first-class technology that fits the unique requirements of your project to get operations running smoothly and efficiently. Our pallet handling equipment is trusted to increase throughput and flexibility while lowering overall costs of operations.

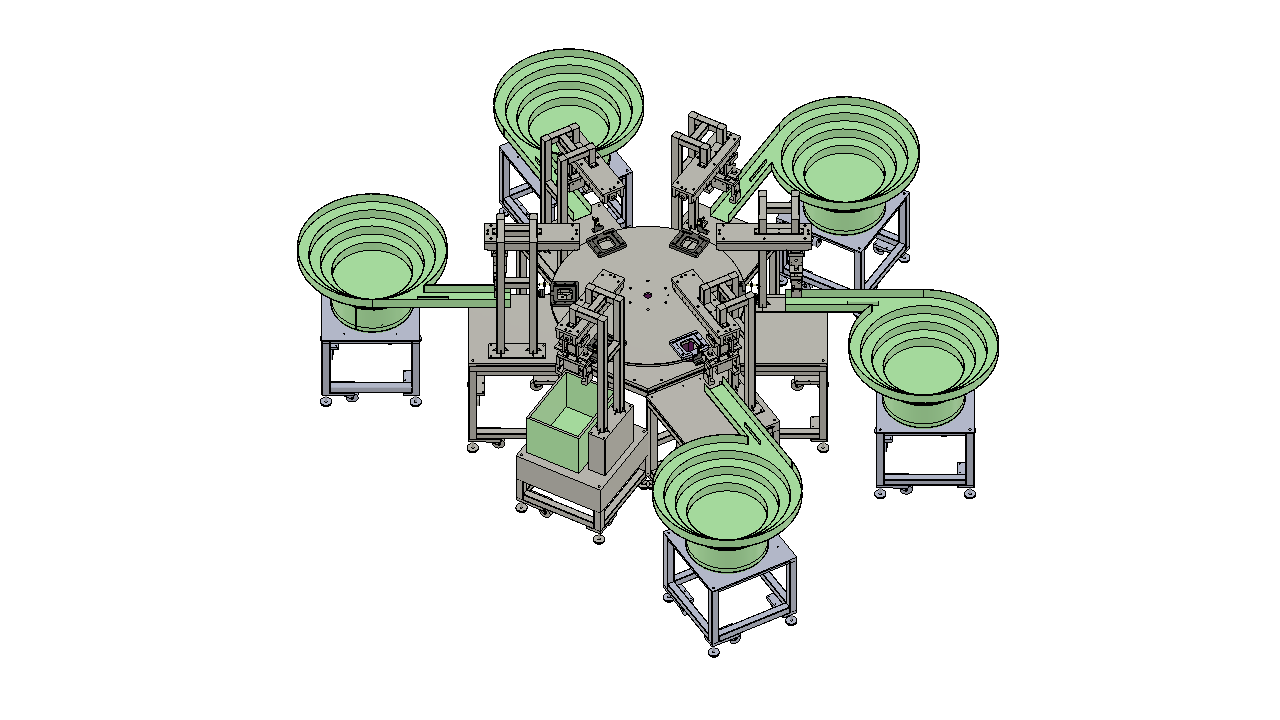

Vibratory Bowl Feeders

Suprak Vibratory Bowl Feeders are utilized to orientate and discharge parts in a repeatable position in the assembly process with no manual intervention.

What makes a feeder system of Suprak, so valuable is the capability to feed complex orientation components and also High Feed Rate. By using robust tooling practices and material selection, our vibratory feeder systems are constructed to ensure high efficiency and reliability even after n number of cycles.

Our feed systems are custom designed to the specific application depending on the component. Our bowls are crafted from a range of materials like stainless steel, aluminum, MS with different coatings implemented depending on the application